2025 Truck Nats Chassis focus - Alex Richards

This truck began its life as one of the first production runs designed and produced by Chad Parks (an AE team driver and original owner of Ignite Design RC). I had helped Chad by machining parts he needed for the original exhaust manifold when he was doing prototypes, at the time, I was switching from AE to X-ray for 10th scales, so my T6.1 was a willing donor truck to convert.

The basics.

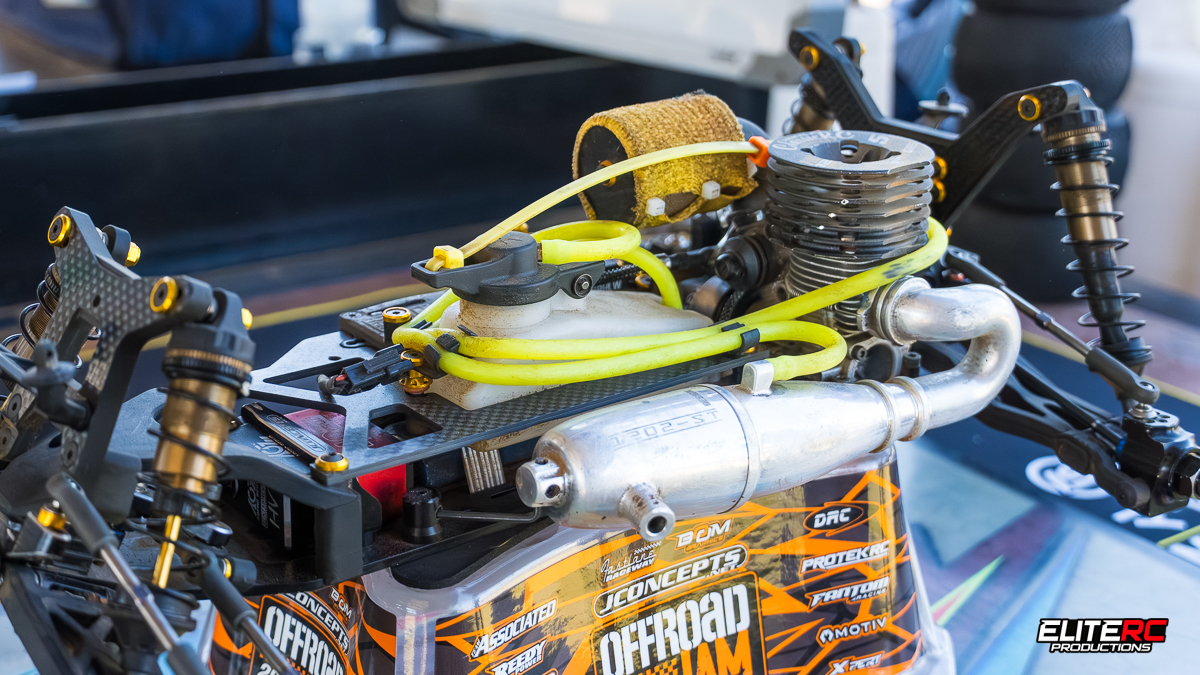

This truck largely remains a t6.1, as the arm inserts on the rear arms, flat front arms, and narrower rear pivots (pre b6.3) all benefit the truck over some of the newer geometry and designs, especially in low-grip outdoor conditions. I use a Sanwa M17, AGFRC Servos (33kg shorty for throttle/brake, 40kg standard HV for steering), all powered by a Protek 2100mah lipo receiver battery. The engine is a Classic RC Company JW12 5 port Launch Edition.

The Modifications

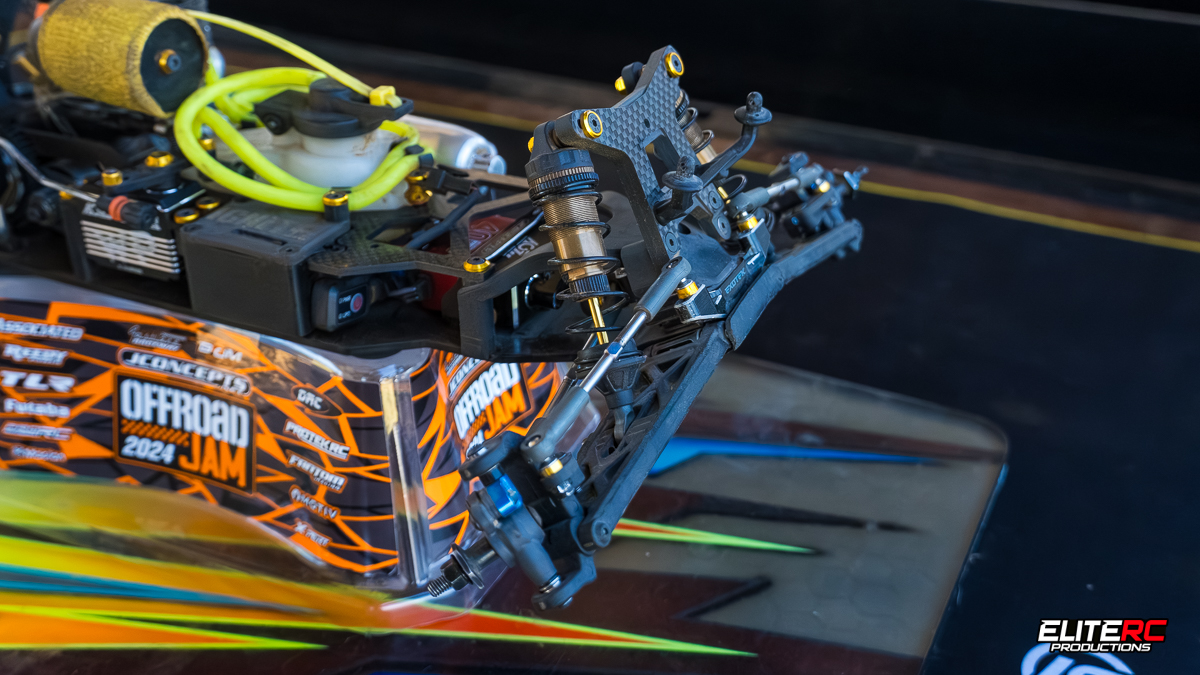

Starting at the front of the truck, the most obvious modification is the B7 adjustable KPI Front end. Having KPI in a 2wd stadium truck really helps numb corner entry and calm down the rear end, with more natural rotation in the center of a corner. In a gas truck, where weight bias is significantly further forward and can’t be moved back like the electric version, this helps driveability and is one of the easiest modifications to help improve the platform. Since my Mayako 8th scales were some of the first to have adjustable KPI in a C-hub configuration, I tested this setup at last year’s truck nationals and really found it was a huge difference-maker in the ability to push the truck comfortably. A Jconcepts alloy steering rack setup ensures the truck stays pointed in the right direction.

Jconcepts titanium upper shock standoffs – anodized gold to match the truck – attach the 13mm Kashima shocks to the Revolution Design 5mm Carbon shock towers front and rear. In the rear, many people run two Associated towers stacked together, and I found these Revolution Design parts are more than stiff enough to hold up, and are thinner than two stock towers without the need for very long shock screws or odd shock geometry. I run 2×1.5 + 2×0.7 hole 2.5mm pistons in the front, with 400cst oil and a white V2 truck spring, and 2×1.6 + 4×0.8 pistons and 400 cst oil in the rear with a green V2 truck sping. I also run the +4 shock ends in the rear for more droop when necessary and because of the amount of rear toe-in, find the truck is much more stable with the lower shock ends mounted with a 2mm ballstud spacer on the back of the rear arms.

Most of the middle of the truck is stock. I use the old carbon top deck and Xray tank that comes with the original conversions. The top deck has had o-rings added in the screws going into the front chassis brace/top plate for a bit of flex, and the same thing is done on the transmission brace that is over the clutch in the rear. Jimmy Woodley of Ignite Design came out with a great 3-piece quick-change motor mount that makes servicing the engine or clutch a breeze. The JW12 has a very unique powerband – partially due to the clutch, which is incredibly important in gas truck. I use a 3-shoe clutch, with two aluminum (1.1 and 1.0 springs) and one carbon shoe (0.7 spring). This is the slide carb variant of the 5 port motor and it absolutely screams and has plenty of low-end grunt to pull a taller clutchbell/spur gear ratio. This engine runs great with an Ignite Design 1-piece tuned pipe/manifold.

One of the difficulties Chad had was sourcing a spur gear for this platform, and to get the gearing as close as possible to the GT2 (Arguably the last “modern” gas truck) he had to use a 66 tooth spur gear that required the transmission to be spaced 1mm off the chassis. I have since switched to an Arrma 57t spur gear and removed the 1mm trans spacer to return the C and D block and transmission to their original location on the chassis. I do run a brass C-block, but that is the only added extra weight on the truck. The transmission is an associated “layback” transmission common from the b/t6.1/2 but has been upgraded with a steel idler gear for durability.

I run the T6.1/B64 style rear alloy hubs from associated, with newer 3.5mm turnbuckles and ballcups all around. I use factory axles in the front, but a very narrow 5mm hex in the rear over the stock 8.5mm hexes. The newest modification to the truck was to use the b74 extended CVA axles in the rear, with t5m 86mm dogbones. This has been the final piece that the truck really needed to gain confidence on power and to keep the rear end in check and hooked up, and it performed very well all weekend.

I stuck with J concepts Double Dees for the mains in green compound and mounted them to JC Racing Products 5-spoke wheels for a bit of vintage flair. The body is a JConcepts F2 for the Traxxas Rustler, which is significantly wider and clears the exhaust more easily. It also provides more room overall as it’s a bit taller to clear the head and air filter. I think it’s a better-looking body than the t6.1 F2, and I painted it for myself through AJRC designs, my painting business.

I have been racing RC for over 30 years, and some of the first time racing was in gas truck. If you feel like you like a challenge, enjoy setting up a unique vehicle, that is an absolute blast to drive. I think gas truck is one of the premier classes to run and I hope to see the class continue to grow back into prominence.

I want to thank Jimmy Woodley, Chad Parks, Mirko Rossi (Nova engines), and the crew from Shaws RC in Ardmore OK for putting on this race every year (The ORIGINAL Truck Nationals!), as well as Lance and Sam from Shaws for running a smooth, predictable, and fun weekend with an incredibly unique and cool festival vibe. I also want to thank Chuck Kleinhagen with Fastlane Raceway here in Kansas City, my home track for his support and giving us a place to race here at my home track and all of my Mayako crew and customers for their support.

Now we just convince JQ to produce a Mayako gas truck 😉